Progressive stamping. Metal stamping presses up to 600 tons.

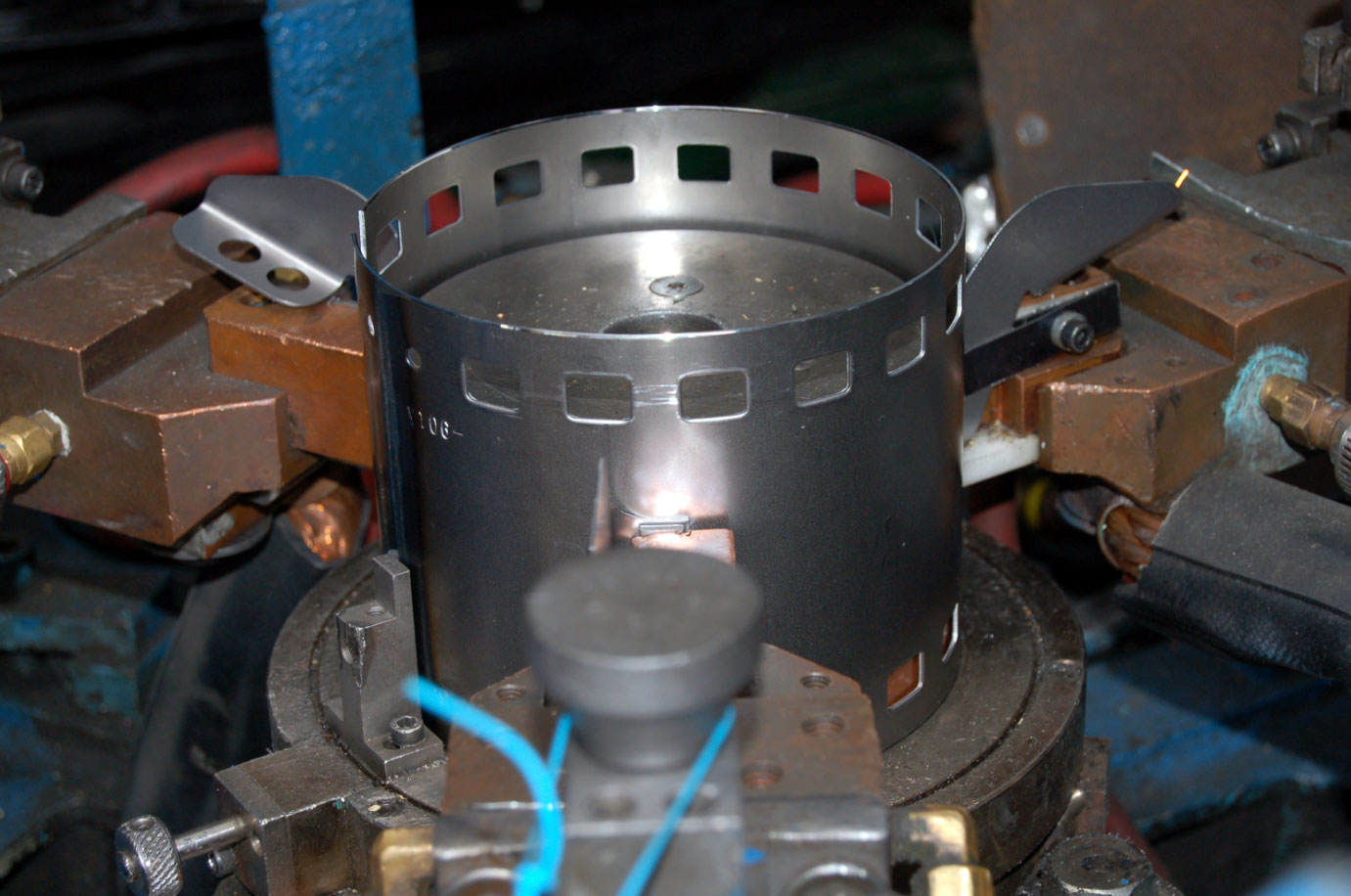

Deep draw stamping of housings

Tumble-deburr, deburr with ceramics

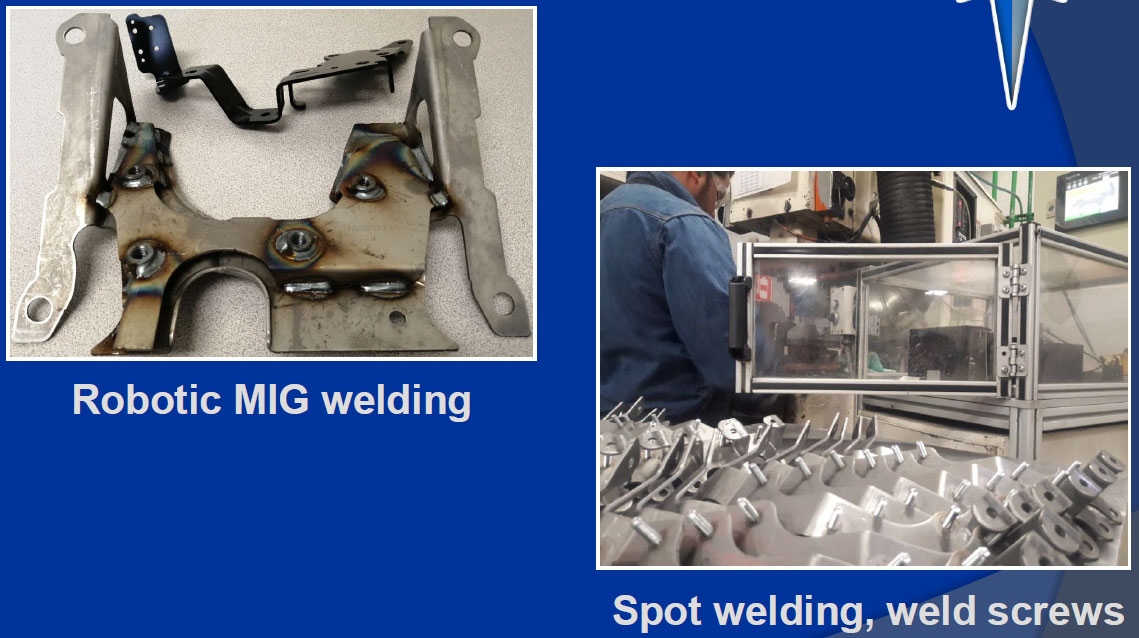

Robotic MIG welding

Electrocoating black and gray (e-coat)

Motor housing for HVAC fabricated with turn-key equipment

HVAC motor housings with gray electrocoating

Powder coating

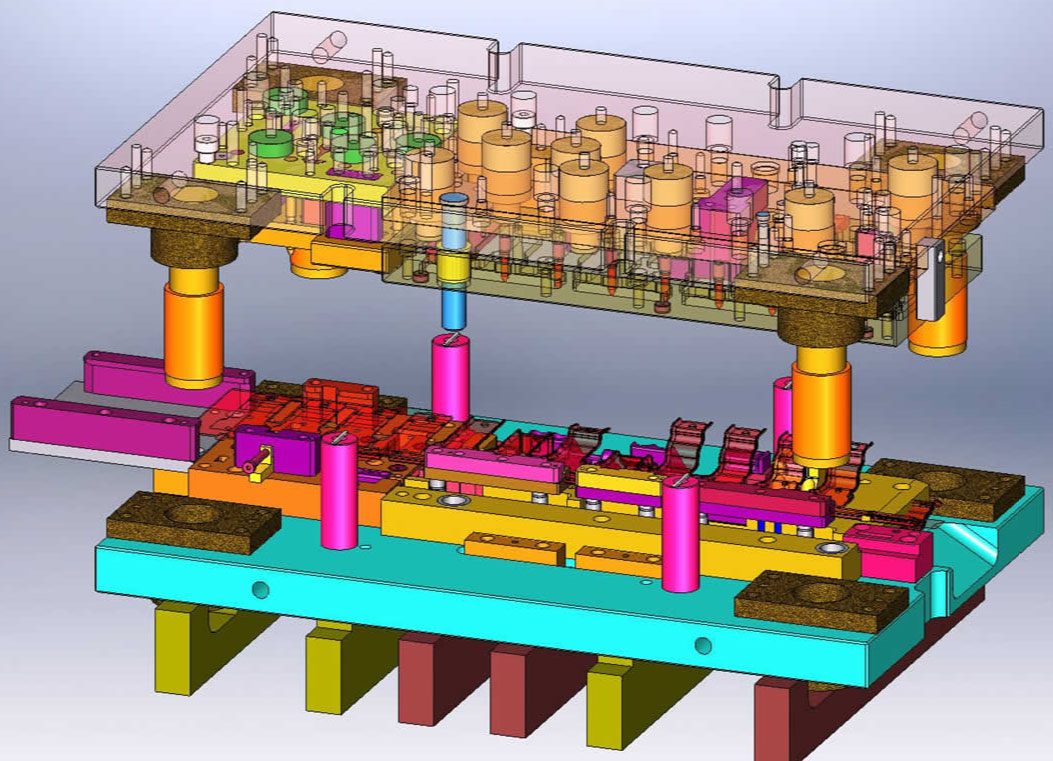

Progressive die design and fabrication with Solidworks

Automotive brackets with in-die nut insertion and in-die tox – Cost benefit: assemblies done during the progressive stamping operation, avoid secondary operations.